I distinctly remember when the tags on the Knickerbocker MFG clothes that I scrimped and saved for ceased to read “Made in USA.” When I first noted the new “Made in Portugal” tags, I felt robbed. Like many of us raised in this clothing sphere, I had come to consider MiUSA as the zenith of manufacturing.

Preoccupied, as I was, with my Red Wings and White Oak Cone Mills denim, I had deluded myself to believe that a product made in the United States was innately better than one made almost anywhere else. I had also overlooked a move made by many highly-esteemed brands to Portugal. A transition that continues to draw high-end brands, seeking the very best in scale and production.

Portugal’s Textile Tradition

Lisbon, the capital of Portugal.

As countries go, Portugal was well-equipped to build a lasting legacy of quality manufacturing. Many of the factories and producers on which modern brands like Our Legacy and Universal Works really are multi-generational affairs, their roots stretching back over centuries. In stark contrast with American factories, many of which have been shuttered in the last 40 years, Portugal’s manufacturing roots go much deeper, into the very fabric of the nation’s identity.

Portugal, unlike many of its neighbors, lost control of its largest colonies in the early 1800s, notably with the independence of Brazil. While other European powers clung to theirs well into the modern era, Portugal was forced to re-evaluate its economy. In light of these marked changes, Portugal needed to change the way it did business, and in order to do that, needed to renegotiate the terms of its long-held trade treaty with England.

Despite the close relationship between England and Portugal, the terms of this treaty strongly favored the English. It covered all facets of Portuguese trade and commerce, but one in which the treaty was significantly lax, was textile production. A cottage industry of woolen and eventually cotton-weaving had long existed in the country and eager to raise the nation’s profile, the country fostered growth in this sector.

The rise of industrialization eventually coincided with this already-thriving industry, causing a boom in textile production, one which skyrocketed with the founding of Portugal’s colonies in Africa—a new market that demanded cotton garments.

No Longer Made in USA

Workers at a Fashion Nova factory. Image via NY Times.

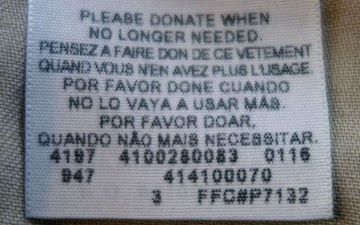

Andrew Livingston, owner and designer of Knickerbocker, echoed my initial misgivings about the shift away from the U.S., “American manufacturing meaning better quality and working conditions is naive, that’s what I initially thought with KMFG.”

Even qualified designers with impressive resumes could be taken in by the myth of American manufacturing. The American heritage boom of the late 2000s and early 2010s conjured an idyllic image of high-quality production, squeaky clean facilities, and livable wages. But that was never entirely the case.

Recently, in Los Angeles, this mirage of ethical manufacturing has evaporated. A New York Times investigation publicized Fashion Nova‘s egregious mistreatment of workers (paid far far below minimum wage) and alleged sexual-harasser, Dov Charney’s, newest venture, LA Apparel, flouted covid era safety regulations in his factories, sickening hundreds.

Cloaked in a a self-serving aura of goodwill and ethics, American manufacturers have rested on their laurels. Even in the heart of liberal, forward-thinking cities, negligent manufacturers can sneak by, simply by throwing an American flag label on their product.

Where Convenience Meets Quality

Dan Snyder, the founder and designer of Corridor NYC, has been working in Portugal for over eight years, first lured to the country by their luxurious brushed flannel. “I drove around the country and I toured any Portuguese factory that is working with like anyone from Universal Works… to everybody. I went through all these factories and the quality of manufacturing is really good. The factories are just regular people working in good conditions. It’s extremely extremely regular.”

Dan Snyder (right) in a woolen mill in Southern Portugal. Image via Dan Snyder.

Dan was careful not to criticize those who choose to work in the United States, but he explained how his trips to Portuguese factories contrasted with his American experience. Unlike back in the states, where working conditions vary widely—from the very best to the very worst, the Portuguese factories tended towards the better, “I didn’t see a single factory that I would feel the least bit uncomfortable working in on a daily basis.”

Brice Ndoumbe, who heads production for Norse Projects, addressed some of the reasons why Portuguese manufacturing has remained so strong, “Portugal is still a country where factories (and state) keep on investing in their industrial means of production which combined to their longtime know-how of specific products makes them more competitive than ever today.”

The benefits for European-based brands like Norse Projects extend beyond the quality of production. Ndoumbe explains, “Working inside the EU, when everybody is talking about sustainability is also for us a good way to say that we are proud to work with people who are fairly paid for what they produce, and offer a lot of transparency.”

Even for Snyder, across the pond, Portugal’s centrality is crucial. Why produce a “Made in USA” shirt, when the fabrics are made on the other side of the globe? “You’re still shipping fabrics across the world,” Snyder pointed out, “For me, it’s about getting to a place where if we were designing a fabric, we are making the garment in the same place. So it’s a really consistent product.”

The proximity of textile-makers to the manufacturers was another reason Andrew Livingston brought KMFG to Portugal, “Much more advanced in terms of production and machines they’re using. Footprint is an issue, they have a rich textile history. Having textiles closer to manufacturers is huge—cuts down on shipping costs.” Lower prices and less transportation not only translates to a lower cost for customers, it amounts to a lower carbon footprint.

Multi-Generational Trades

Image via Universal Works.

When trying to determine just what separates Portuguese manufacturing from American, Dan hit on an important difference. “Because it’s no longer a part of the culture. Garment production is no longer a part of the U.S. culture. So there’s not people who have been at a factory for 30 years, there’s no new blood. [In Portugal] people are continuing to work in these factories because they pay well, the conditions are good, and it’s a profession. In the U.S. it’s ceased to be a profession.”

In The Guardian‘s coverage of the covid-19 outbreak at Los Angeles Apparel, their reporters found that many of those lured to the factory were undocumented workers, many of whom had been laid off in the hospitality and service industries. Undocumented workers, due to their legal status, are far more vulnerable to abuses and less likely to report them.

Though there are American factories with a conscience, (Dan Snyder commended Save Khaki in LA for their quality and transparency.) bad actors have cast a shadow on the splendor of Made in U.S.A. in the last few decades.

In the twentieth century, which saw the advent of the modern factory, there was a pride in textile work in the United States. (Although as we recently discussed, this pride was often White Supremacist in origin.) Eventually, American labor law fell by the wayside, with the federal minimum wage scarcely rising to meet modern cost of living.

Star denim. Image via Knickerbocker.

Andrew Livingston admitted, “the median wage [in Portugal] may be lower, but the quality of life is much better, from what I’ve witnessed.” This is large in part due to Portugal’s inclusion in the E.U. in 1986, which increased transparency and accordingly, worker protections.

Those family-owned factories that survived until the 80s were undoubtedly saved by the European Union’s oversight. With healthcare, parental leave, and other such crucial aspects of a social safety net provided, factory work needn’t be a dirty secret, it provided for families just like any other career.

Corridor NYC’s sneaker factory in Porto, Portugal. Image via Dan Snyder.

Snyder articulated the marked increase in quality of working with a multi-generational factory in Porto.

So about a year and a half ago, I started working on a sneaker and we placed the sneaker in Portugal, and that’s where the sneaker’s made and it’s made in a factory outside Porto. The factory itself is actually more of a dress shoe factory. They’re one of the biggest suppliers for Europe, for moccasins, driving moccasins. And they mostly work with leathers. And I think that’s why the shoe came out so nice because a lot of these factories are super old. This guy, I think his great grandfather started the factory. So I’m working with the great grandson. And so there’s like a lot of pride of ownership. And so people have been there for super long time.

The country that now produces some of the world’s best woolens and leathers may not be considered as acclaimed or luxurious as Italy, but an influx of highly-regarded brands might speak to the contrary. Portugal isn’t a manufacturing utopia, nor is it the silver bullet to the evils of the fashion world writ large, but the country showcases a manufacturing environment where heritage and honesty coincide to make rock-solid product.

The Final Say

Image via Clark.com.

In our final exchange, Snyder clarified his position one last time, “I’m only referring to my process and why I moved away from U.S. manufacturing and that I don’t think that it’s right or wrong—that’s just been my process.”

The move away from American manufacturing isn’t an indictment of the country as a whole, but speaks to an increasingly difficult domestic environment, one too often exploited and one made challenging to operate in. For many brands, Portugal serves as an exciting, (not-so) new frontier, where you don’t need to dig too deep to find a clean, well-run factory full of healthy, well-treated employees. Though Portuguese manufacturing has by-and-large been found to be consistently benevolent and positive, no country is a monolith.

After all, “Made in USA” isn’t just one thing. For every shady middleman working with Fashion Nova, there is an honest Runabout Goods or a fastidious Roy and for every irresponsible Dov Charney, there is a responsible, conscientious brand like 3sixteen. There are still stalwarts reminding us of why MiUSA has such a strong appeal and there is just as much merit to taking business to a place like Portugal, where your dollar goes farther and renders an excellent product.