Denimheads fetishize the means of production more than just about any other community. Not only do we want to know what brand made the jeans, we want to know where the cotton came from and who milled it.

These questions, however, aren’t easily answered by the average consumer who rarely sees their jeans prior to a store shelf or postage box. In this article, we’d like to highlight some of the key denim mills in the world producing selvedge fabric to give you a glimpse of what goes on where.

Japan

Amhot Mills

Amhot Mills

Founded on August 13, 1993 and based in Osaka, the sheer impenetrability of Amhot Mills‘ internet presence is enough to pique the curiosity of any casual web browser. In fact, you must email someone at the company to request a log-in code to even visit their website. And while their web design may seem like something out of the dark ages, their fabric offerings are anything but. Like many Japanese textile developers, Amhot takes cues from Japan’s long and vibrant history of weaving and sewing, but gives them a modern edge.

Kuroki Mills

Kuroki Mills, on the other hand, does have a functioning website and it tells an incredible story. Founded in 1950 by Tamotsu Kuroki, it wouldn’t be until 1960 that they would begin to produce denim. Originally, they vat-dyed their denim (somewhat heretical in the denim community), but by 1965, the mill began rope-dying. This gave their product a more authentic look and allowed the fabric to develop fades that mimicked and even rivaled those of the original American blue jean makers. By 1970, the company was producing denim exclusively, and in 1988, they moved to the factory pictured above. Kuroki now supplies denim to some of the heaviest hitters in the industry including 3sixteen (check their tour of Kuroki here).

Japan Blue/Collect Mills

People say that an organization is only as good as its weakest link, and there are certainly no weak links at that conglomeration known as Japan Blue Group from Kojima. Everything began with Collect, the actual mill and fabric provider, which was founded in 1992. For 14 years, meticulously weaving denim on antique looms was enough, but by 2006 they decided to take that product and apply it to their own designs and founded the first of two in-house denim brands. They called it Momotaro for the mythical boy in the peach, and even gave their jeans a signature pink-line selvedge to do their name-sake justice. In 2010 Japan Blue Jeans was founded, selling similarly high-quality jeans at a lower price point.

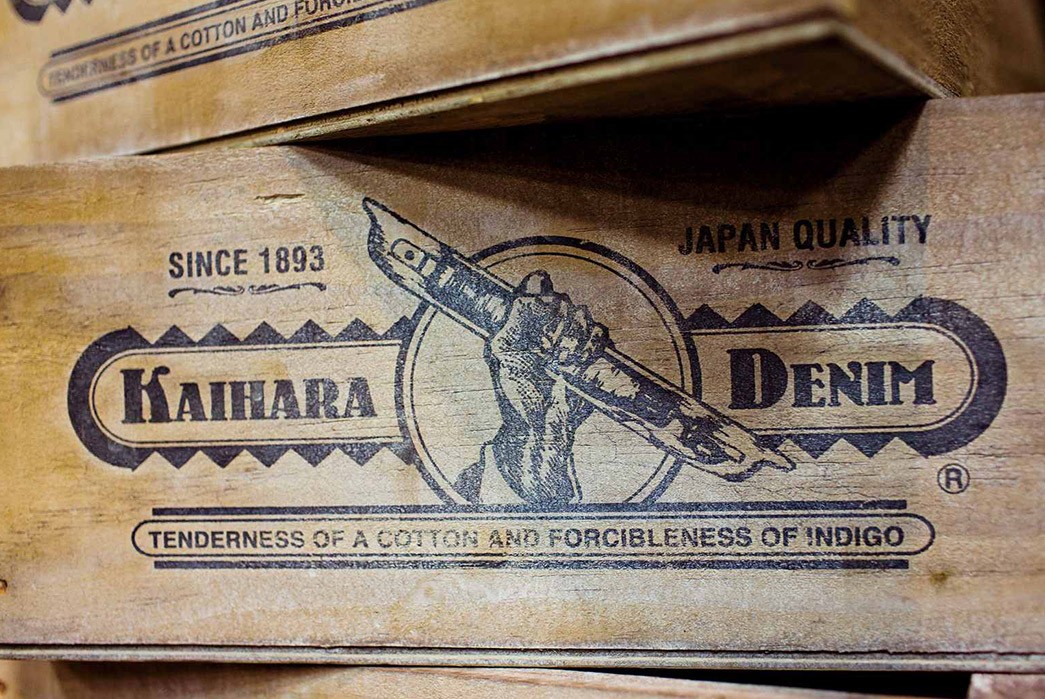

Kaihara Mills

Kaihara Mills. Image via JCrew

Kaihara Mills was established in 1951, but its origins lie in its founder’s first-ever indigo weaving endeavor in 1893. Sukejiro Kaihara was an indigo expert, something conveyed in nearly all his company’s endeavors. For years, Kaihara Mills has been a ceaseless innovator, patenting and developing new machines to improve the dyeing and weaving processes. In 1970, they independently developed a rope-dying machine that they insist was the first in Japan (although the jury’s out on this one—Kuroki says they started doing this five years earlier), and Kaihara never stopped improving their equipment. In 1977, they set a world record for most rope-dying ever done in a single month of production. At present, Kaihara continues to grow and adapt, providing denim for brands like J. Crew and Nudie.

Nihon Menpu Mills

IMAGE: Via Paul Trynka and Loomstate

Nihon Menpu is an old mill, first established in 1917, but the company didn’t fully commit itself to denim production until 1985. This happened at a time when the global standards of denim production were beginning to decline and mass production on high-speed looms was the most common and profitable way to do things. But Nihon Menpu slowed things down by using old-fashioned looms to make a higher-quality selvedge denim. Their yarn-by-yarn philosophy has certainly paid dividends, they now provides denim to one of the great American denim brands, Rogue Territory.

Nisshinbo Mills

Nisshinbo Mills has existed in one way or another since 1907 [but a decent picture of their factory is still in the works -Ed], when it was established as the Nisshin Cotton Spinning Company, and they produce all kinds of textiles. (For example, in 2004, they began production of an anti-bacterial and anti-odor fabric.) But despite the success of some higher-tech fabrics, Nisshinbo’s specialty remains their ring-spun denim. Largely phased out in the 1970s, ring spun denim is a more labor-intensive process, which gives the surface of denim a more irregular and vintage look. Nisshinbo supplies denim to brands like Taylor Stitch and Left Field.

Kurabo Mills

Kurabo‘s esteemed history begins with its founding in 1888 in Kurashiki, Okayama. But it wasn’t until 1970 that they entered the denim business. They made a big splash with their KD-8 Kurabo denim, which was marketed as the first denim ever made in Japan. (The histories are awful fuzzy about this, aren’t they?) But even considering the contested legacy, it’s absolutely certain that Kurabo was one of the most crucial trailblazers in Japan’s denim history because it was their denim that was used by Big John, one of the first Japanese jeans company.

Toyoshima Mills

Toyoshima was founded in 1841 and now functions as a fabric wholesaler. They also produce some wild novelty fabrics like bamboo and hibiscus blends. Their innovative denim can be found in brands like Freenote Cloth.

Everywhere Else

As you may have noticed, Japan takes center stage when it comes to weaving selvedge denim these days. That said, there are a handful of other important mills in other parts of the world.

Cone Mills

Our article: Meet Your Maker: Cone Mills Of Greensboro, North Carolina

Cone Mills is the last of a dying breed—the last selvedge denim mill in the United States. Founded by Moses and Caesar Cone in 1891 in Greensboro, North Carolina, the company got its big break with the so-called “Golden Handshake” in 1915, made with Levi Strauss Co. This informal handshake deal made Cone Mills the exclusive denim-provider for Levi’s, and the deal lasted until Levi’s moved production overseas, although premium Levi’s are still cut from the same old Cone denim. Cone Mills product could be identified by the red line in their selvedge edge and the characteristic inconsistencies in the fabric comes from a slight bounce in the wood floors as the Draper X3 looms do their thing.

Candiani Mills

On the floor of the Candiani mill.

Candiani got its start in 1938 outside of Milano, Italy. Candiani has been family-run since its inception, and after over 75 years in the business has declared themselves the greenest denim mill in the industry. They have won a number of awards for their commitment to sustainability, and with their two factories, they are the largest denim producer in Europe.

Berto Mills

Also hailing from Italy is selvedge denim mill Berto. Founded by two brothers in Bovolenta in 1887, Berto supplies regular non-selvedge denim, of course, but does things the old-fashioned way too. Their line called “Blue Selvedge” relies on 1950s “Picanol style mechanical scaffoldings” to give their denim that authentic feel. Specially trained operators and repair-people keep the machines and this antiquated form of production alive.